- RUBBER ROLLERS PLUS PAD CONFIGURATION IS GOOD FOR CALIBRATING AND FINE SANDING

- HARDENING TREATMENT MACHINING CENTER TO PROCESS THE MACHINE FRAME

- ASSEMBE DYNAMICALLY BALANCED ROLLERS ON THIS MACHINE AND OTHER GOOD QUALITY PARTS, ALL OF THESE TO ENSURE THE ENTIRE MACHINE HAS HIGH PRECISION AND LONG TERM RELIABILITY

- ECCENTRIC SHAFT IS ADOPTED. LIFTING CONTROL BY PNEUMATIC TURN-OVER IS EASY TO OPERATE

- TOUCH SCREEN WHICH IS EASY TO OPERATE

| CNC Router | |

| Work stroke | 1300*2500*50mm |

| Spindle Brand | HQD 9.0KW auto tool change |

| Spindle Speed | 18000r/min |

| Drive system | Japan Yaskawa 850W servo drive |

| Inverter | Fulling 11KW |

| Germany guide rail | 25mm |

| Positioning cylinder | 4 pcs |

| PVC vacuum adsorption | Total 6 areas, 2 holes in each area |

| Vacuum Pump | Domestic water cycle 7.5kw |

| Tool change device | 10 tool automatic change(line type) with 4 pcs tool holder |

| Reducer | Helical gear reducer,2m rack |

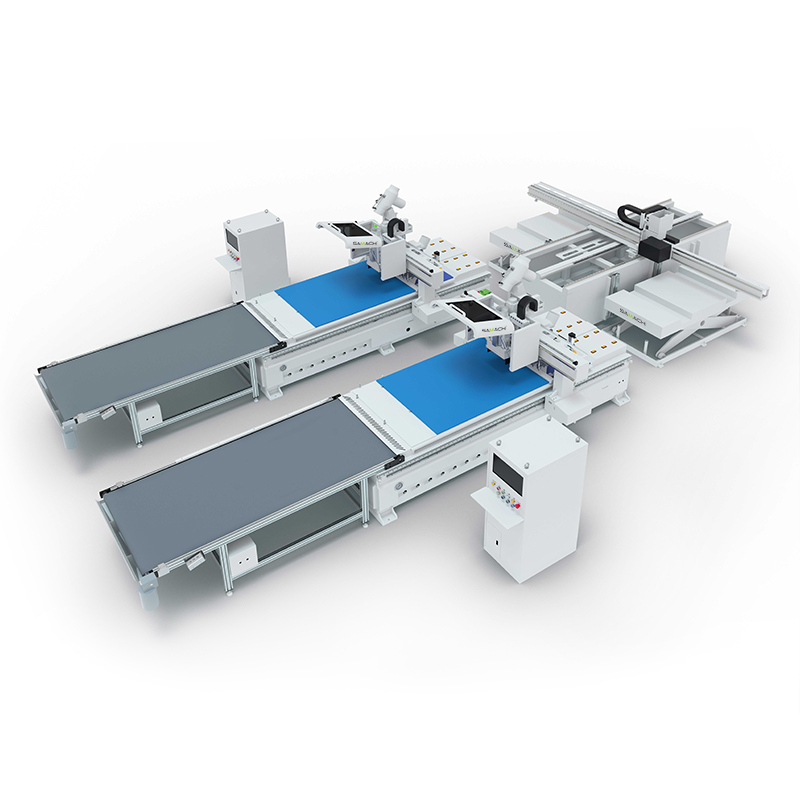

| Pushing device | Auto loading, unloading device (lifting worktable and belt conveyor platform) |

| Max. work speed | X/Y axis: 25m/min, Z axis: 10m/min |

| Operation instruction | G-code, *.NC |

| Operation system | Syntec FC computer control system (display monitor and handwheel) |

| Auto Label Sticking | |

| Size | 3700*4460*1726mm |

| X axis motor | 1.3kw |

| Y axis motor | 0.85kw |

| Feed Lifting Table | |

| Worktable size | 2200*1000mm |

| Overall size | 2200*1100*470mm |

| Max lifting height | 1300mm |

| Weight | 700kg |

| Output Belt Table | |

| Overall size | 3000*1340*880mm |

| Motor power | 0.55kw |